CWIEME in Berlin erneut ein Erfolg

The Dr. Dietrich Müller GmbH, leading supplier of electrical insulation materials for electric motors; Generators and transformers, presented at the international trade fair Coil Winding, Insulation & Electrical Manufacturing, which took place from 04.06-06.06.2013 in Berlin, at booth 3425 in hall 3.2 a multitude of technical solutions, which are specifically for applications in the electrical and electronics industry are adapted.

Application range of flexible and solid insulating materials

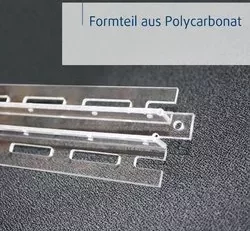

The focus was on the comprehensive range of Insulating parts, which is manufactured from an extensive range of solid and flexible electrical insulation materials.

In addition to the flexible materials of the brands Nomex, Mylar, Teonex, Ultem, Lexan, ArpaxX, which are processed into punched and molded parts, the Ahlhorn-based company also presented laminated materials. Here, complex parts are manufactured on the most modern CNC machines, which are used in electrical engineering, in the manufacture of generators, and in transformer construction.

In the area of manufacturing flexible insulating materials, Dr. D. Müller GmbH has all the necessary processing technologies, such as B. slot insulation machines, Cover slide automatic machines, feathering machines, and slitter winder. For the production of phase insulation from z. B. Nomex 411 respectively. Freudenberg H1062 can fall back on an extensive repertoire of existing tools.

Technical application advice

The employees of the application technology department at Dr. Dietrich Müller and were able to offer the trade fair visitors comprehensive advice during the trade fair: Insulating materials were recommended according to the required framework conditions, tailored to the respective application. In doing so, all requirements with regard to the technical parameters as well as the respective necessary approvals (here in particular the UL systems) are taken into account.

Prototypenservice „Quick-Prototype“

The Dr. In the future, Dietrich Müller GmbH will offer its customers the opportunity to receive prototypes for prototyping within 48 hours under the motto „Quick Prototype“. Conditions for this are the submission of DXF drawings and the selection of stored electrical insulation materials. Laser cutting machines with a table size of 1200 x 900 mm, cutting plotters (flatbed and roll plotters) for parts with a width of 1200 mm and water jet cutting technology for blanks with dimensions of 3000 x 2000 mm are available for the production of prototypes.

ArpaxX-Aramidpapiere

In addition to the materials widely used in the electrical industry, Dr. Dietrich Müller GmbH also presents the expanded range of ArpaxX aramid papers. In addition to the already presented types L, N and S, the type T was presented at the trade fair, which combines the proven properties of the ArpaxX N variant with the lower prices of the ArpaxX L variant.

New organizer

Overall, the Dr. Dietrich Müller GmbH satisfied with the new organizers of the fair. Interesting new forms of advertising were made possible and an extensive program of lectures was organized.