Seals: important components

The decisive influence seals have on the function and service life of machines and systems is often overlooked.

Proportional valves, for example, are restricted in their function and endangered from dirt particle sizes of 3 μm.

Rolling bearings, on the other hand, are significantly impaired in terms of their service life and can be damaged by water content in the lubricant of just 200 ppm.

Seals basically fulfill two tasks for rotating or linear components: on the one hand they protect the sensitive inner workings of the machine elements from contamination, on the other hand they protect the environment from the escape of lubricants or hydraulic equipment, for example.

Gasket selection criteria

There are basically three criteria when selecting the right seal:

1. Structural specifications: It is important to consider how the components relate to each other.

2. Chemical and physical loads: Here it must be taken into account how large or different the pressure conditions are and how the temperatures behave. It must be checked whether friction occurs. An important consideration is whether or not there is a need to seal against corrosive substances that could attack the sealing material.

3. In the area of economics and assembly, the number of seals required must be taken into account and how the maintenance effort is to be assessed.

What types of seals are there?

There are basically two types of seals:

Dynamic seals are used where the interfaces move. Static seals, on the other hand, are found where the interfaces are at rest. Examples of static seals are z. B. metal O-rings, flange gaskets or liquid seals. In general: Since dynamic seals can only be implemented with a gap, albeit a very small one, between the sealing surfaces, 100% tightness cannot be guaranteed. However, these "leaks" are often intentional, since the minimally escaping substances serve as a lubricant. However, the leakage must not be too large to avoid serious damage.

materials for seals

The operating temperature range and media resistance are the most important criteria when selecting materials for seals.

Nevertheless, the mechanical and technological values of an elastomer compound must be given due consideration, since these are also decisive for the life of the seal.

In the following sections we show which ones 6 important sealing materials for processing into gaskets and flat gaskets:

- Flex seal NBR

- Flex seal FKM

- Flex seal EPDM

- Flex Seal VMQ

- Flexseal TPU

- Flex seal PTFE

our 6 most important sealing materials

Seal Material Flexseal NBR - Acrylonitrile Butadiene Rubber

NBR is one of the most widely used materials for seals, which is used in many areas due to its good mechanical properties and resistance to mineral oil-based lubricating oils and greases. However, good resistance to fuels is usually only possible with special mixtures.

The properties of Flexseal NBR are mainly determined by the acrylonitrile content (ACN between 18% and 50%). A low ACN content of the NBR material leads to good low-temperature flexibility, but limited resistance to oils and fuels; as the ACN content increases, the flexibility of the Flexseal NBR at low temperatures decreases and the oil and fuel resistance increases.

The standard NBR material has a medium ACN content to cover a wide range of applications as a sealing material with balanced properties. Flexseal NBR has good mechanical and technological values, e.g. B. high abrasion resistance and good resistance to lubricating oils and greases based on mineral oil, hydraulic oils H, HL, H-LP, flame-retardant hydraulic fluids HFA, HFB, HFC, aliphatic hydrocarbons, silicone oils and greases, water up to approx. +80 °C.

On the other hand, Flexseal NBR is not resistant to aromatic and chlorinated hydrocarbons, fuels with a high aromatic content, polar solvents, glycol-based brake fluids and HFD flame-retardant hydraulic fluids.

The ozone, weather and aging resistance of Flexseal NBR is low. In most applications, e.g. B. when the material is wetted with oil, the low ozone, weather and aging resistance does not have a negative effect.

Flexseal NBR is also available as a fabric-reinforced version. Cotton or synthetic fiber fabrics can be used as the basis for rubber fabric materials. Cotton fabric is standard for hydraulic seals. Outside of the standard, a whole range of other types of fabric and almost all elastomers are available for impregnation.

Gasket Flexseal FKM – fluorocarbon rubber

Flexseal FKM materials are characterized by their very high temperature and chemical resistance. In addition, the very good aging and ozone resistance, the very low gas permeability (and thus good suitability for use in a vacuum) and the self-extinguishing fire behavior should be mentioned.

The FKM standard sealing material shows very good resistance properties in mineral oils and mineral fats, aliphatic, aromatic and chlorinated hydrocarbons, fuels, flame-retardant HFD hydraulic fluids and many organic solvents and chemicals.

In addition to the standard FKM materials, various special compounds are available, which are tailored to special sealing applications due to the different composition of the polymer chains and different fluorine contents (65% to 71%).

FKM is generally not resistant to hot water, steam, polar solvents, glycol-based brake fluids and low-molecular organic acids.

Sealing material Flexseal EPDM - Ethylene Propylene Diene Rubber

EPDM materials generally show good resistance to hot water, steam, aging and chemicals, and a wide range of thermal applications. They are used in many general sealing applications. They are divided into sulphur-cured and peroxide-cured types, with the peroxide EPDM mixtures being more thermally stable and having a significantly lower compression set.

EPDM has good resistance to hot water and steam, detergents, caustic soda and caustic potash, silicone oils and fats, many polar solvents, many diluted acids and chemicals. Special grades are recommended for glycol-based brake fluids.

EPDM materials are absolutely incompatible with mineral oil products (lubricants, fuels).

The service temperature limits of the Flexseal EPDM gasket material are -45°C to +130°C

(-50 °C to +150 °C peroxide cross-linked).

Gasket material Flexseal VMQ – silicone rubber

Silicone rubbers are particularly notable for their wide range of thermal uses and their outstanding resistance to ozone, weathering, and aging. The mechanical properties of silicone are rather low compared to other elastomers.

However, glass fiber reinforced silicone types are also available, which are mechanically much more resilient than pure silicone sheets. In general, silicone materials are physiologically harmless, ie they are used in the food and medical sectors, among other things.

The silicone standard material can be used in the temperature range from – 55 C to +200 ͦ C and is resistant to water (up to 100 ͦ C), aliphatic engine and gear oils, animal and vegetable oils and fats.

Flexseal silicone is generally not resistant to fuels, aromatic mineral oils, steam (up to 120 ͦ C for short periods), silicone oils and fats, acids and alkalis.

Sealing material Flexseal TPU - thermoplastic polyurethane

Flexseal TPU materials belong to the group of thermoplastic elastomers (TPE). The strength of the TPU lies in the combination of its good physical and chemical as well as processing and economic properties. TPU is manufactured as standard on thermoplastic injection molding machines and has been established in sealing technology, particularly in hydraulic applications, for many years.

TPU materials stand out from classic elastomers due to their significantly higher mechanical strength. Other excellent material properties include high abrasion, wear and extrusion resistance, high compressive strength, and high tear and tear strength.

The TPU material shows good flexibility (even in the upper hardness range) in the temperature range from -40 °C to +100 °C and very good aging and ozone resistance. TPU can be used well in mineral oils and greases, hydraulic oils H, HL, HLP, silicone oils and greases, flame-retardant pressure fluids HFA and HFB and water up to 50 ͦ C as well as pure aliphatic hydrocarbons.

Sealing material Tecfilm PTFE - Polytetrafluoroethylene

PTFE is a fluorinated plastic. PTFE has a number of positive properties that have become indispensable in sealing technology. It is characterized by its almost universal chemical resistance, the wide temperature range from -100 ͦ C to +250 ͦ C, an extremely low coefficient of friction and the resulting very good sliding properties, no stick-slip effect, special rigidity and the almost unlimited ozone , weather and aging resistance. Almost all known hydraulic media, lubricants, chemicals and solvents cannot harm PTFE.

Only elemental fluorine and alkali metals attack it at high temperatures and pressures. Pure PTFE contains no extractables that could migrate and affect adjacent materials. It is therefore physiologically harmless and also particularly suitable for food, pharmaceutical and medical applications. PTFE is not combustible and therefore does not pose an additional hazard in the event of a fire.

PTFE is not or only slightly elastic. For this reason, PTFE sealing elements are activated by elastic preload elements in the form of O-rings or stainless steel springs.

However, PTFE also has certain disadvantages, such as B. the tendency to cold flow or creep of pure PTFE under pressure. However, these weaknesses are compensated for in the sealants by adding fillers. fillers, e.g. B. bronze-filled compounds, give the PTFE the ability to adapt to most service conditions.

Seals with aramid fibers

Aramids are organic synthetic fibers that are characterized by special properties. In the form of seals, these are particularly suitable for higher temperatures, under pressure and for liquid media.

Aramid fiber gaskets are characterized by high tensile strength and high compressive strength. They are heat and fire resistant and have good sealing properties and excellent chemical resistance. The seals with aramid fibers are available in various combinations, each with its own property profile. Even the smallest quantities can be produced using special recipes on state-of-the-art calenders.

Our Aramid fiber gaskets meet the requirements of the DVGW (German Association for Gas and Water) for drinking water approval. This makes them ideal for use in water pipes.

Depending on the region and requirements, we can supply material with different approvals (KTW, W270, WRAS, ACS).

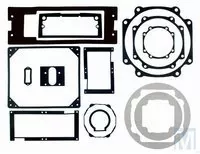

Stamped seals

We manufacture stamped parts from the materials listed, which can be supplied in an assembly-optimized version in adhesive and non-adhesive versions. Our transfer adhesive SP 61321 and various transfer adhesives from 3M are used for the adhesive finishing of the sealing materials. Even small quantities of seals can be manufactured without the use of tools. Water jet cutting or alternatively a plotter is suitable for this.

In addition to the flat gaskets, we also supply O-rings.