Activities against Corona

Our company took an active part in the fight against Corona. Of course, we have developed our hygiene concept, which is based on the recommendations of the Federal Ministry of Health and the RKI.

However, it was clear early on that we also want to make a contribution with our expertise in production and logistics:

We have developed the following activities in the individual areas:

Plant Converting: Nonwovens as wage work

In the converting plant in Durmersheim, large quantities of meltblown nonwovens and staple nonwovens are made up according to the specifications of the new mask manufacturer. In some cases, multi-layer structures are cut and made available to customers. Nonwovens are processed by all well-known manufacturers. In the course of increasing demand, the machine stock was expanded by two roll cutting machines.

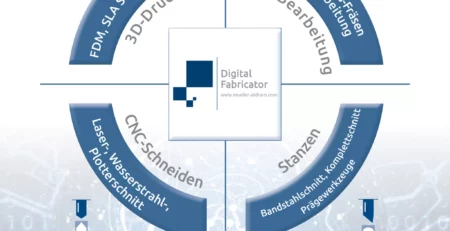

Plant Flexibles: face shields, 3D printing and valves

In the Flexibles plant, a face visor was developed as part of a research project and also led to a corresponding certification. For many other visor manufacturers, we have punched the actual foils and provided them with the appropriate certifications.

In the 3D printing department we printed up to 500 visor mounts per day and completed and delivered them with the foils and cut rubber strands punched in the stamping department.

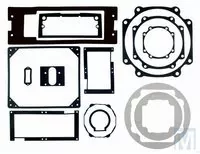

We have supplied pre-assembled valves for mask manufacturers. Here we procured injection molded parts and stamped the valve diaphragms ourselves.

Composites plant: partition walls

The focus of the composites plant is on the production of partition walls made of transparent plastics for retail, schools and gastronomy. Many standard designs were supplied, but we also made many special designs.