8 ready-made thermal management solutions

In the automotive industry and medical technology, there are always greater challenges in the field of electronics. The heat to be dissipated presents increasing challenges.

In this post, we present 8 ready-made thermal management solutions:

- Standard thermal pads

- Thermal pads

- Thermal Compound

- phase change materials

- thermal glue

- double-sided thermal tape

- silicone-free graphite foil

- liquid gap filler

Standard thermal pads

Standard thermal pads are suitable for smooth and parallel surfaces that do not show a gap to the naked eye. The material evens out microscopic unevenness in the contact surfaces, which improves the thermal interface and thus increases heat dissipation. They are electrically insulating and typically come in thicknesses between 0,1mm and 0,3mm to optimize thermal impedance.

Some films come with an optional adhesive and some use fiberglass reinforcement to improve handling properties.

There are also some silicone-free versions.

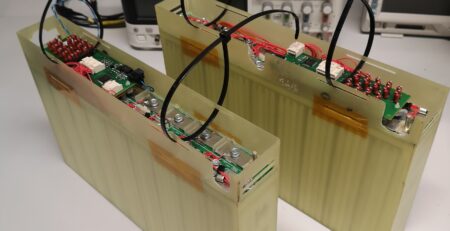

Thermal contact between suboptimal surfaces requires a softer, thicker material to bridge the gaps between the active component and the heatsink. They are softer than standard foils and, thanks to their excellent compressibility, create optimal thermal contact with electrical insulation at the same time.

Supplied thicknesses range from 0,5-12,0mm. Other thicknesses or shapes are available upon request. Some materials have fiberglass reinforcement or are double-layered to improve handling. Silicone-free versions are also available.

Thermally conductive pastes are thixotropic mixtures with good plasticity and very low thermal resistance. Due to the non-crosslinked silicone, there is no drying out or leakage of the silicone components. There are also silicone-free versions.

Phase Change Materials (PCM)

Phase Change Material consists of a combination of hotmelt waxes. These foils even out even the smallest unevenness between the power module and the heat sink, thus improving the contact between the surfaces and increasing the heat transfer. There are designs with electrical insulation based on polyimide filmn or PEEK filmn as well as electrically non-insulating versions based on copper or aluminum foils.

Thermally conductive adhesive is available as a two-component adhesive based on epoxy resin for the permanent attachment of components such as CPU, GPU, BGA, heat sink, etc., as a one- or two-component variant as a silicone adhesive or as an adhesive film that is glued to standard films or gap fillers and helps to assemble components.

Double-sided thermal tape

Thermally conductive tapes are ceramic-filled, double-sided tapes with excellent, permanent adhesion. When used correctly, no mechanical fixation is required. They also offer good thermal performance and excellent electrical insulation.

silicone-free graphite foils

Graphite foils are based on 100% pure graphite or natural graphite. They have anisotropic thermal conductivity, with very high thermal conductivity in the XY plane and yet very good thermal conductivity in the Z axis. Due to their thermal behavior, they are often used as heat spreaders, but they also offer a cost-effective solution when electrical insulation is not required.

liquid gap filler

This gap filler are two-component silicone materials that are applied through a mixing tube or poured into complex shapes. The gap filler liquids harden at room temperature within 1-24 hours and thus enable wet-on-wet assembly of any component without an additional heating step. Automatic dosing systems enable economical large-scale production.