Materials that improve battery performance

Materials that improve battery performance

Although the utility of electric vehicles (EVs) has made significant strides over the past decade, much work remains to improve their yield and reduce costs. At the heart of this challenge is the battery system, where designers must attempt to balance competing constraints such as cost, power and weight in order to optimize vehicle performance. Often the most promising path to a solution lies in the battery pack assembly, where each design iteration must consider potential tradeoffs for thermal management, susceptibility to electromagnetic and radio frequency interference (EMI/RFI), and environmental/physical stress. MG Chemicals has an extensive portfolio of material solutions covering common challenges encountered in battery systems.

Functional adhesives for bonding and protecting

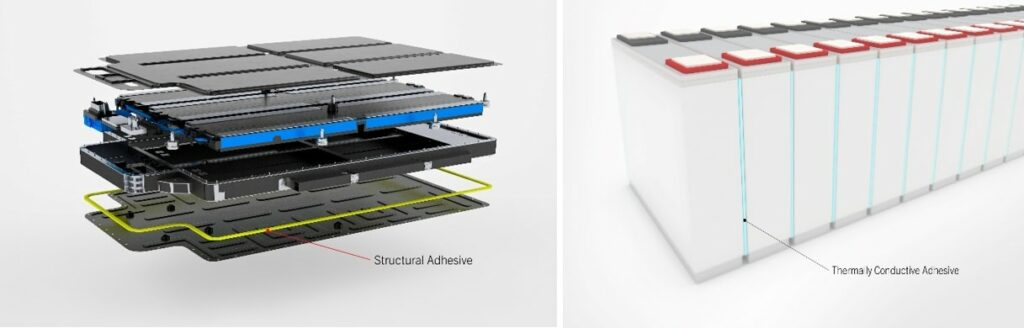

The primary function of an adhesive is to bond two surfaces sufficiently to provide functional mechanical support. However, specialty adhesives with secondary properties such as flame retardancy and thermal conductivity have additional properties that are of value when used in battery pack assemblies. These adhesives also improve thermal shock resistance and reduce battery weight by eliminating welds.

Structural and thermal adhesives

The leading battery type for electric vehicles is the lithium-ion battery, mainly due to its high energy density and longevity. However, a disadvantage of this battery is the risk of fire if the battery is punctured or improperly charged. To reduce this risk, designers use flame retardant materials like our 9200FR to build firewalls around the battery pack to prevent the spread of fire. This adhesive is a 2 part flame retardant structural epoxy that offers exceptional bond strength and is UL94 V-0 certified by Underwriter Laboratories. It is also an excellent replacement for PET films used along the cooling trough to bond modules, whether in a cylindrical or prismatic array.

Thermal management is a critical design parameter for battery packs, as individual cells of the modules heat up during charging, necessitating fast and effective heat dissipation. Modules are bonded together within the pack array using thermally conductive adhesives such as our 8329TFF and 8349TFM that facilitate effective lateral heat transfer out of the pack and regulate temperature. These materials connect the modules to cold plates and can be used as gap fillers between the top of the package and the lid to aid in heat dissipation.

Figure 1: Layer diagram of battery pack with structural adhesive (left) and cell array with thermally conductive adhesive (right)

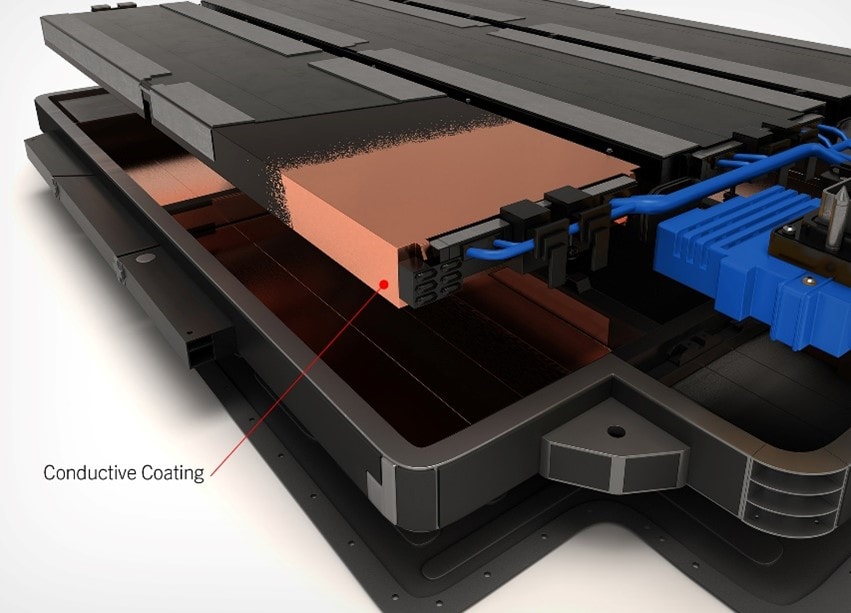

Conductive coatings for noise reduction

Electrically conductive coatings are 1 or 2-component systems containing conductive fillers such as nickel, copper and silver, with binder systems being standard in most industrial coatings. These coatings are a quick and easy means of metallizing plastics for two primary purposes: shielding electrical equipment from EMI/RFI and creating traces. With battery packs, designers must shield the battery from neighboring devices both inside and outside the vehicle to prevent crosstalk and subsequent malfunctions. Conductive coatings such as our 841AR and 842AR can be applied to the inside of the battery pack lid and case assembly to block interference from external magnetic and electric fields. These coatings allow automakers to move from heavy metal battery cases to lightweight plastics, reducing overall weight and improving efficiency. In addition, these conductive coatings reduce the electrical resistance between active materials and the aluminum foil along the wall of battery cells, improving charging and discharging performance.

Figure 2: Conductive coating along the battery cell wall

Environmental Protection

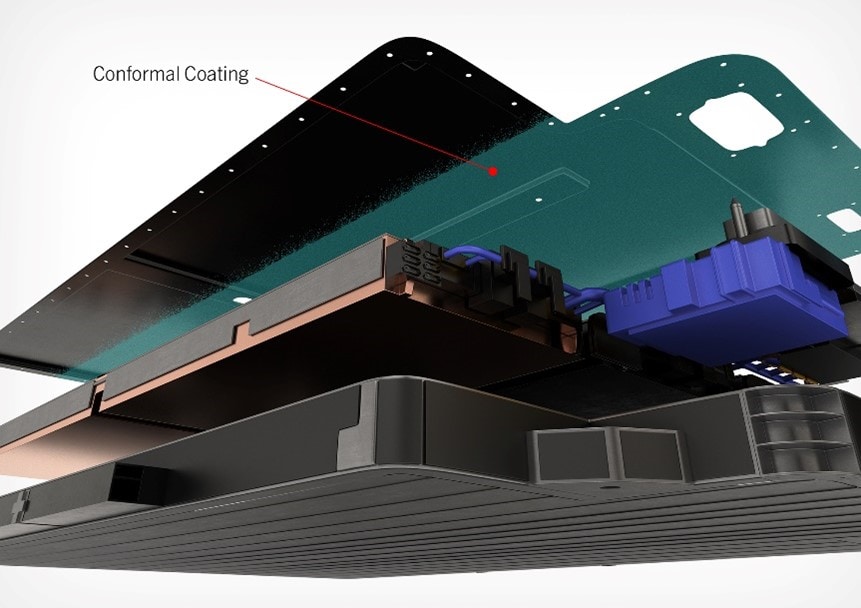

Vehicle components are exposed to a variety of contaminants, ranging from the fluids circulating within the vehicle to salts and other corrosive elements from the external environment. To ensure the longevity of EV batteries, coatings and resins are applied to protect sections from corrosion, shock and arcing. Dielectric coatings such as our 4223F , 4225 , 4200UV and 4226A are used to coat electrical components such as printed circuit boards, busbars and cold plates that are susceptible to failure from corrosion or arcing.

Liquid resins like our 834B and 834HTC potting compounds cure to a hard, rigid surface and can be used to fill gaps between cells and ensure everything stays firmly in place. The potting compounds are both thermally conductive and flame retardant, helping to prevent overheating and uncontrolled fire in the event of ignition.

Figure 3: Conformal coating on the battery pack circuit board

Conclusion

Improving the battery performance of electric vehicles (EVs) through the use of special materials is an ongoing task. The main task of designers is to balance competing constraints such as cost, power and weight to optimize vehicle performance. MG Chemicals offers materials that cover common battery system design challenges. This includes functional adhesives that not only bond, but also have additional properties such as flame retardancy and thermal conductivity.

An example is 2FR 9200 part flame retardant structural epoxy which offers exceptional bond strength and is UL94 V-0 certified by Underwriter Laboratories. It can be used to build firewalls around the battery pack to prevent the spread of fire. Another key material is conductive coatings like our 841AR and 842AR, which can be applied to the inside of the battery pack lid and case assembly to block interference from external magnetic and electric fields. These coatings allow automakers to move to lightweight plastics to reduce overall weight and improve efficiency.